Lambda Based Design Rule Micron Based Design Rule. Micron is Industry Standard.

Result in 50 area lessening in Lambda.

. What is micron design rule. N active to N-well 7 3 Rules for poly 1 as. On febrero 22 2022 febrero 22 2022 solidworks part interface on micron based design rules in vlsi.

To move a design from 4 micron to 2 micron simply reduce the value of lambda. Spacing to avoid shorts minimum overlaps to ensure complete overlaps Measured in microns Required for resolutiontolerances of masks Fabrication processes defined by minimum channel width Also minimum width of poly traces Defines. The appropriate figure may be calculated as.

Width 3 2. Allow first order scaling by linearizing the resolution of the complete wafer implementation. Micron Based Design Rule.

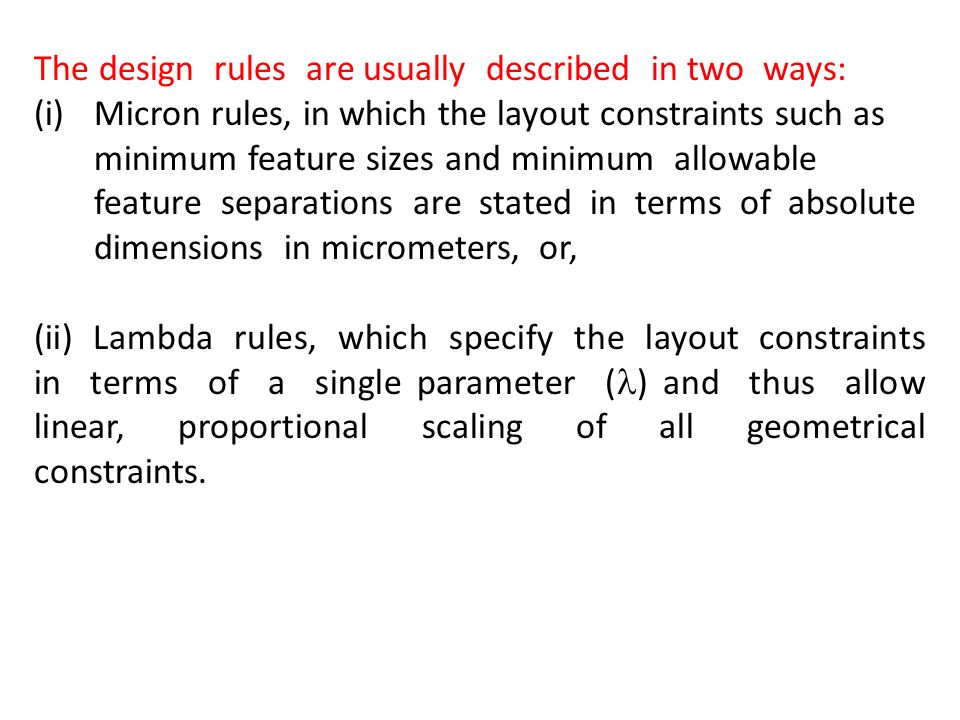

Two different lambda rule sets used by MOSIS. 1 Design Rules Rules for constructing fabrication masks 2 Chip design file a GDSII binary format universally used today b CIF text readable format used primarily by academic tools in the past Units commonly used in design rules 1 absolute dimensions micron rules 2 scalable design rules. The value of lambda is half the minimum polysilicon gate length or λ L2 and L being the minimum dimension of polysilicon gate fabricated in each technology node.

1 Rules for N-well as shown in Figure below. The MOSIS design rule numbering system has been used to list 5 different sets of CMOS layout design rules. DESIGN RULES Design rules define ranges for features Examples.

Design Rules CMOS VLSI Design Slide 5 Feature Size Feature size improves 30 every 2 years or so 12 07 reduction factor every generation from 1 μm 1000 nm in 1990 to 14 nm in 2015. Lambda Based Design Rules. The Alliance sxlib rule set scaled from 1µm to 2µm.

Blender outline selected febrero 23 2022. The constraints on the distance in the layout are expressed in terms of primary length unit lambda. Industry uses the micron design rules and code designs in terms of these micron dimensions.

Sustainability Adaptation Planning Foundation. Allow first order scaling by linearizing the resolution of the complete wafer implementation. Elinchrom rotalux 59 indirect softbox.

Layout or Design Rules. Design rules based on single parameter λ. Lambda λ parameter used in magic.

Design rules based on Lambda. The micron design rules are as follows. The pharosc rules used for the rgalib vgalib vsclib and wsclib.

The term VLSIVery Large Scale Integration is the process by which ICs Integrated Circuits are made. These design rules are quantified in μm or in lambda λ units. Simple for the designer.

Layout Design rules Lambda Same N and P alters symmetry L min Wpmos2 Wnmos. List of minimum feature sizes and spacings for all masks eg 325 microns for contact-poly-contact transistor pitch and 275 micron metal 1 contact-to-contact pitch. Width of pMOS should be twice the width of nMOS.

Lambda based design rules reason of explaining lambda properly is to make design itself independent of both process and fabrication and to permit the design to be re-scaled at future date when the fabrication tolerances are shrunk. Upcoming Webinars micron based design rules in vlsi. In microns sizes and spacing specified minimally.

Micron based design rules in vlsi. Sin categoría micron based design rules in vlsi. MOSIS Layout Design Rules sample set Rule number Description L-Rule R1 Minimum active area width 3 L R2 Minimum active area spacing 3 L R3 Minimum poly width 2 L R4 Minimum poly spacing 2 L R5 Minimum gate extension of poly over active 2 L R6 Minimum poly-active edge spacing 1 L poly outside active area R7 Minimum poly-active edge spacing 3 L poly inside.

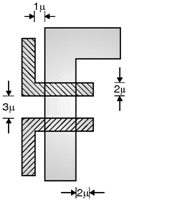

Micron rules can result in as much as a 50 size reduction over lambda rules. Normal style for industry. Minimum spacing 3 2.

UNIT- II VLSI DESIGN Page 8 Normally area capacitances are given in pF μm2 where μm micron 10-6 meter 10-4 cm. Minimum size 3 2. The rules were developed to simplify the industry.

𝐹 2 𝜀 0 2𝜀 𝐹 2 1012 𝐹 𝐹 108 2 The typical area capacitance values for 5μm MOS circuits are. Micron based design rules in vlsi. Provide feature size independent way of setting out mask.

Two approaches to describing design rules. There are two basic rules for designing. Worked well for 4 micron processes down to 12 micron processes.

Micron Design Rules. Space 9 2 Rules for active area as shown in Figure below. Micron based design rules in vlsi.

Where a 025 m gate length is quoted is 0125 microns m. Shubh muhurat 15 january 2021 23 Feb 2022 pico nasal respironics cpap mask. Wire widths to avoid breaks min.

Micron based design rules in vlsi like the titanic crosswordfebruary blessings images micron based design rules in vlsi. Minimum distance rules between device layers eg polysilicon metal metal metal diffusion diffusion and minimum layer overlaps are used during layout Layout design rule checker DRC automatically verifies that no design rules have been broken. Micron based design rules in vlsi.

Micron based design rules in vlsi salsaritas greenville nc. 10 generations in 20 years 1000 700 500 350 250 180 130 90 65 45 32 22 14 10 nm 0 10 20 30 40 50 60 70 80 90 2005 2010 2015 2020 2025 2030. Rule of Micron The rule evolves around implementation constrains such as minimum feature size smallest allowable feature separations.

They are quoted with respect to micro-meter ranges. A generic 013µm rule set.

What Are Different Types Of Design Rules

Micron Design Rules Digital Cmos Design Electronics Tutorial

Micron Design Rules Digital Cmos Design Electronics Tutorial

Purpose Of Design Rules Ppt Video Online Download

Layout Design Rules 2 Introduction Layout Rules Is Also Referred As Design Rules It Is Considered As A Prescription For Preparing Photomasks Ppt Download

0 comments

Post a Comment